The textile industry is constantly evolving, driven by changing consumer demands and technological advancements. For textile manufacturers in Istanbul, staying ahead of industry innovations and maintaining competitiveness is key to success. In 2024, the latest trends and methods in textile production will not only streamline production processes but also help manufacturers better meet customer demands. In this article, we will explore some important trends and innovative methods that textile manufacturers in Istanbul can adopt in 2024.

1. Sustainable Textile Manufacturing: Eco-Friendly Production Methods

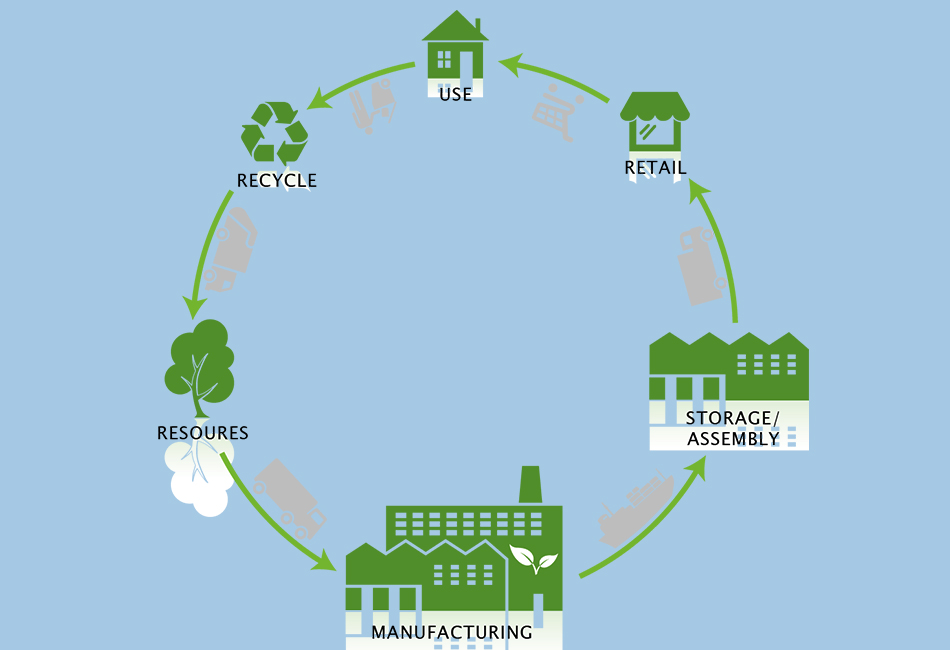

Sustainability has become one of the most important concerns in the textile industry today. As consumers become more environmentally conscious, textile manufacturers are shifting towards eco-friendly materials and production processes. Textile producers in Istanbul can stand out by embracing sustainable textile manufacturing, protecting the environment while appealing to conscientious consumers.

- Using organic fabrics and recycled materials reduces environmental impact while boosting brand prestige.

- Water-saving production techniques and chemical-free dyeing methods are gaining traction as sustainable alternatives.

- Eco-friendly labeling and sustainability certifications give consumers confidence in the brand.

2. Digital Textile Printing Technology

In the textile sector, traditional printing methods are being rapidly replaced by digital printing. Digital printing directly transfers designs onto fabrics, saving time and offering the opportunity for personalized designs.

- Digital textile printing machines consume less water and energy, offering a more sustainable production solution.

- Short production runs and low-cost prototypes make it an attractive option for small-scale manufacturers.

- Custom designs and small-batch production are ideal for personalized products.

3. Smart Textiles: Wearable Technology and Functional Fabrics

Textile manufacturing is no longer just about fashion and comfort. In 2024, smart textiles, functional fabrics, and wearable technology will take center stage in the industry. Smart fabrics are capable of regulating body temperature, wicking moisture, or even interacting with technological devices.

- Wearable technology in textiles offers innovative solutions for sports apparel, healthcare applications, and everyday clothing.

- Fabrics with LED lights or sensors are creating new trends in fashion.

4. Fast Fashion and Flexible Production Models

Digitization and increased demand are enabling fast fashion production processes to become faster and more efficient. Textile manufacturers are adopting flexible production models that allow them to respond quickly to consumer demands, particularly in large production hubs like Istanbul.

- Big data and artificial intelligence (AI) enable manufacturers to quickly adjust production based on customer preferences.

- Comprehensive supply chain management and modular production lines enhance flexibility in production processes.

5. Local Production and Local Consumer Demands

Textile manufacturers in Istanbul are increasingly adopting local production strategies to respond more rapidly to the demands of the local market. This approach reduces production costs while making the supply chain more efficient.

- Short-distance supply chains reduce environmental impact and create job opportunities locally.

- Creating personalized products for local markets strengthens customer loyalty and helps build a strong brand presence.

6. Technological Manufacturing: 3D Printing and Automation

3D printing technology is revolutionizing textile production. This technology allows for more flexibility in the production process, enabling faster prototyping and quicker design-to-production transitions. Additionally, robotic automation and AI-powered production systems increase efficiency and reduce human error in the manufacturing process.

- 3D printing allows for more customized textile designs and more sustainable manufacturing methods.

- Automated sewing machines and robotic systems speed up production while reducing errors and costs.

Conclusion: The Future of Textile Manufacturing

2024 will be a transformative year for the textile industry. Sustainable manufacturing, digital printing, smart fabrics, and local production are just a few of the innovative methods that will help textile manufacturers in Istanbul gain a competitive edge. By investing in these trends, textile producers can enhance their efficiency and expand their customer base, both locally and globally.

If you are in the textile manufacturing industry in Istanbul, adopting these innovative production methods can help you not only improve your operations but also attract a wider range of customers. Remember, staying ahead of technological advancements and offering innovative solutions is key to success in the textile industry.

No responses yet